Are Handmade Cars Made Using Robotics? Exploring the Future of Auto Manufacturing

In the realm of automobile manufacturing, the traditional perception of handmade vehicles contrasts sharply with the burgeoning world of robotics and automation. As we delve deeper into this fascinating intersection, we seek to answer the pressing question: are handmade cars made using robotics? The answer is not as straightforward as one might think, blending the art of vehicular craftsmanship with cutting-edge technology.

The Art of Handmade Cars

Handmade cars have long been regarded as symbols of luxury and exclusivity. Each model, meticulously crafted by skilled artisans, reflects a level of craftsmanship that mass-produced vehicles simply cannot match. These cars often feature bespoke elements and unique designs tailored to the individual preferences of their owners. However, achieving this high level of craftsmanship comes with its own set of challenges:

- Time-Consuming Processes: Handmade cars require significant time investment, often taking months or even years to complete.

- Limited Production: The attention to detail and skill involved means that production numbers are often low, further elevating the exclusivity of these vehicles.

- Human Error: While skilled artisans excel in their craft, the potential for human error can impact the consistency of quality.

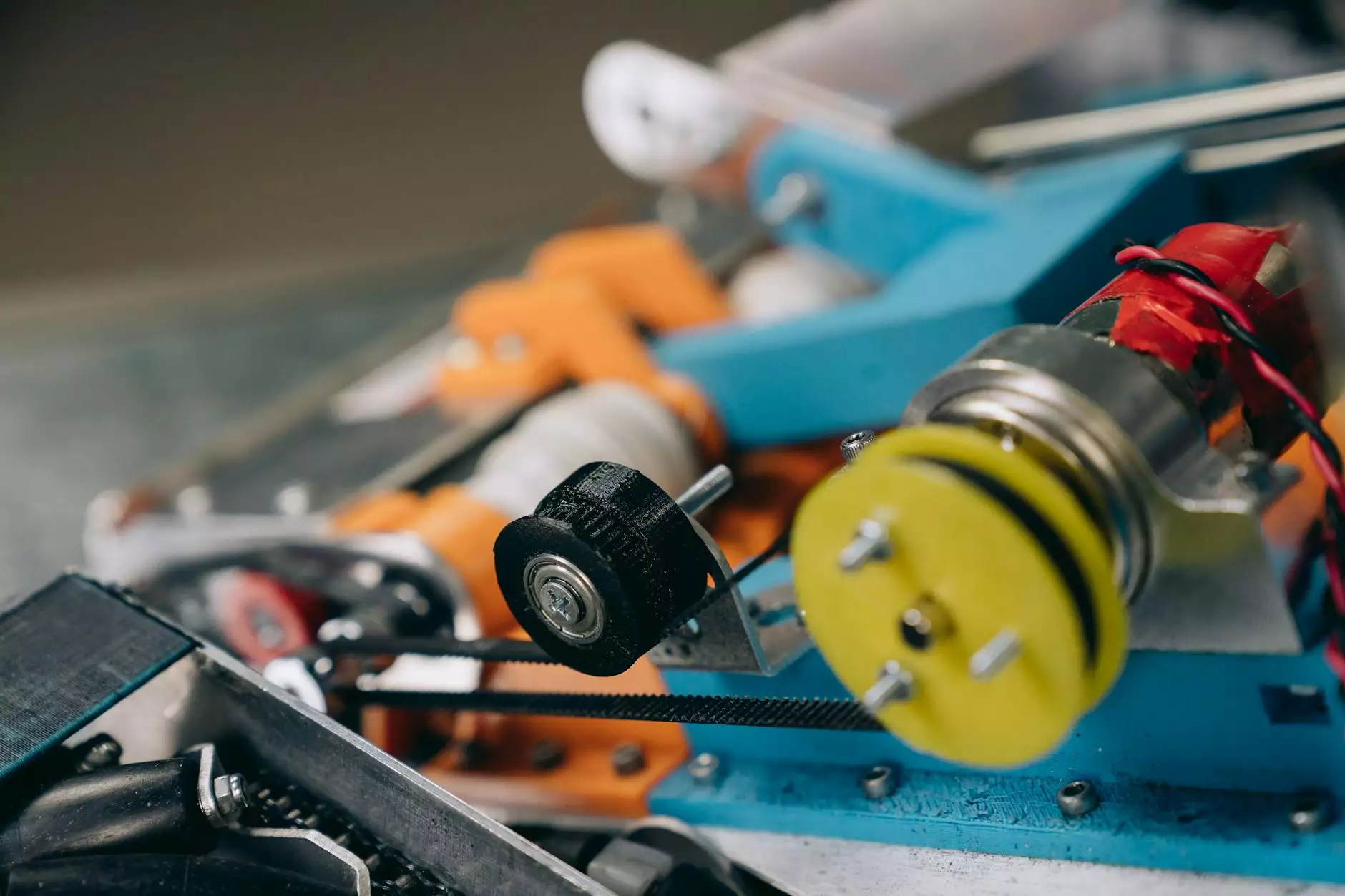

The Role of Robotics in Modern Manufacturing

Robotics have revolutionized industries around the globe, and the automotive sector is no exception. Automated systems enhance productivity, quality, and safety, while significantly reducing production times and costs. Here’s how robotics are transforming the automotive landscape:

- Precision Assembly: Robots can perform repetitive tasks with high precision, ensuring that each component is fitted perfectly within manufacturers' tolerances.

- Reduced Labor Costs: Automation reduces the need for manual labor, leading to significant savings in overhead costs.

- Quality Control: Advanced robotic systems can also monitor quality in real time, identifying defects early in the manufacturing process.

Combining Handmade Craftsmanship with Robotics

The question arises: can handmade cars benefit from the efficiencies of robotics while maintaining their artisanal identity? The answer is a resounding yes, as many manufacturers are now blending old-world craftsmanship with modern technology. This synergy creates a unique product that upholds the values of handmade vehicles while embracing the advancements of modern manufacturing.

Examples of Innovative Vistas

Numerous companies are making headway in this hybrid approach. Here are a few notable examples:

- Pagani Automobili: Known for their bespoke hypercars, Pagani employs robotics for precise assembly but relies on skilled artisans for detailing and finishing.

- Ferrari: While Ferrari maintains a strong handmade tradition, they employ robotic systems for painting and parts assembly to ensure perfect precision and durability.

- Koenigsegg: This manufacturer utilizes robotics for repetitive tasks, allowing their artisans to focus on crafting unique components by hand.

Benefits of Robotics in Handmade Car Production

The integration of robotics in the production of handmade cars fosters several advantages:

- Improved Efficiency: Robotics can complete tasks faster than human workers, considerably speeding up production without sacrificing quality.

- Enhanced Customization: Advanced robotic systems and software allow for greater customization options for buyers, with the ability to easily adjust designs and specifications.

- Consistent Quality: Robots provide uniformity and precision, ensuring that every replica of a model meets the same high standards.

- Expanded Capability: Robotics can handle complex tasks that may be challenging or dangerous for human workers, such as heavy lifting or intricate assembly.

The Future of Handmade Cars and Robotics

The future of the automotive industry, especially in the realm of handmade cars, is poised for transformation. As technology continues to evolve, we can anticipate even more sophisticated robotics entering the manufacturing process, further enhancing the synergy between craftsmanship and automation.

Trends to Watch

As we look forward, several key trends are likely to shape the future of handmade car production:

- Increased Customization: With advanced software and robotics, personalization will reach new heights, allowing car enthusiasts to create vehicles that reflect their individual style.

- Sustainable Practices: Robotics can improve sustainability by optimizing resource usage, minimizing waste, and enhancing energy efficiency in production processes.

- Integration of AI: Artificial Intelligence can pave the way for smarter robotics capable of learning from human craftsmen, enhancing collaborative efforts in vehicle manufacturing.

Challenges of Integrating Robotics in Handmade Car Production

Despite the numerous benefits, integrating robotics into handmade car production is not without its challenges:

- Cultural Resistance: Long-standing traditions in craftsmanship can create resistance to automation among purists who value the human touch.

- Initial Costs: The upfront investment required for advanced robotics can be prohibitive, especially for small manufacturers.

- Skilled Workforce Needs: As robots take on more tasks, the demand for skilled workers who can operate and maintain robotic systems will grow.

Conclusion: The Harmony of Tradition and Technology

In conclusion, as we delve into the question, are handmade cars made using robotics, it becomes evident that the future of car manufacturing lies in the harmonious integration of art and technology. By embracing robotics, manufacturers can enhance their production processes while continuing to uphold the artisanal craftsmanship that defines handmade vehicles.

At fanciro.com, we believe that future automotive creations will embody both the spirit of craftsmanship and the advances provided by robotics. The exciting landscape of handmade car manufacturing, enhanced by technology, promises to deliver unique, high-quality vehicles tailored to individual tastes, setting new benchmarks in the industry.

As consumers increasingly demand personalized experiences coupled with efficiency, the collaboration between traditional craftsmanship and advanced robotics will undoubtedly pave the way for the next generation of handmade automobiles.